What is a Linear Actuator? Definition, Working Principle & Applications

Introduction

A linear actuator is a device that converts rotary motion into linear motion, enabling movement in a straight line. These actuators are widely used in automation, robotics, medical equipment, industrial machinery, and smart home systems.

In this article, we will explore:

- What is a linear actuator?

- How does a linear actuator work?

- Types of linear actuators

- Applications in different industries

- How to choose the right linear actuator?

What is a Linear Actuator?

A linear actuator is a mechanical device that generates linear (straight-line) motion from a power source (electricity, hydraulics, or pneumatics). Unlike rotary actuators, which create rotational movement, linear actuators push, pull, lift, or slide objects in a controlled manner.

Key Features of Linear Actuators:

✔ Converts rotary motion into linear motion

✔ High precision and control

✔ Can be electric, hydraulic, or pneumatic

✔ Used in automation, robotics, medical devices, and more

How Does a Linear Actuator Work?

The working principle of a linear actuator depends on the type of actuator. The most common type is the electric linear actuator, which operates as follows:

- Electric Motor Activation – A DC or AC motor generates rotational motion.

- Gear Reduction Mechanism – A gear system reduces speed and increases torque.

- Lead Screw or Ball Screw Mechanism – Converts rotational motion into linear motion.

- Extension & Retraction – The actuator’s rod or slider moves forward or backward.

- Limit Switches & Sensors – Control the motion range and positioning.

🔹 Example: In an adjustable hospital bed, an electric linear actuator raises or lowers the bed by extending or retracting a lead screw mechanism.

Types of Linear Actuators

There are several types of linear actuators, each suited for different applications:

1. Electric Linear Actuators

- Power Source: DC or AC electricity

- Mechanism: Uses a motor, lead screw, and gears

- Advantages: Precise control, programmable, energy-efficient

- Applications: Smart furniture, medical devices, automation

2. Hydraulic Linear Actuators

- Power Source: Hydraulic fluid pressure

- Mechanism: Uses a piston and cylinder system

- Advantages: High force output, suitable for heavy loads

- Applications: Construction equipment, industrial presses

3. Pneumatic Linear Actuators

- Power Source: Compressed air

- Mechanism: Uses a piston in a sealed cylinder

- Advantages: Fast response time, lightweight

- Applications: Factory automation, packaging machinery

4. Stepper & Servo Motor Linear Actuators

- Power Source: Stepper or servo motor

- Mechanism: Ball screw or belt-driven system

- Advantages: High accuracy, programmable motion

- Applications: Robotics, CNC machines, 3D printers

Applications of Linear Actuators

Linear actuators are used in a wide range of industries, including:

1. Industrial Automation & Machinery

- Conveyor systems

- CNC machines

- Material handling robots

2. Medical & Healthcare Equipment

- Adjustable hospital beds

- Wheelchairs and patient lifts

- Dental chairs

3. Smart Home & Furniture

- Motorized TV lifts

- Electric standing desks

- Automated window blinds

4. Automotive & Transportation

- Car trunk openers

- Electric seat adjustments

- Adaptive suspension systems

5. Renewable Energy

- Solar panel tracking systems

- Wind turbine blade adjustments

How to Choose the Right Linear Actuator?

To select the best linear actuator for your application, consider the following factors:

✔ Load Capacity – Determine the weight the actuator must move.

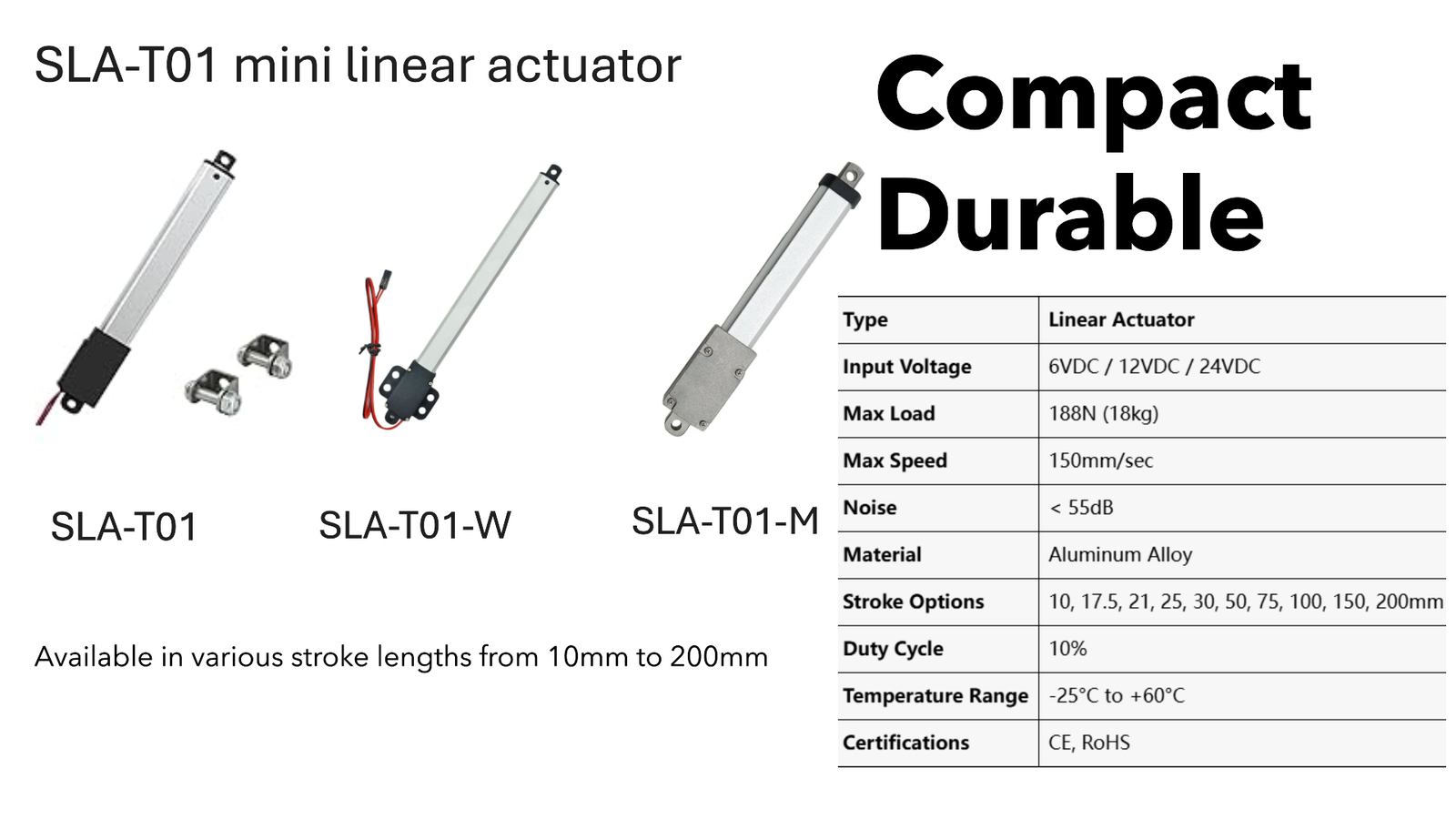

✔ Speed & Stroke Length – Choose the required movement speed and distance.

✔ Power Supply – Select AC/DC depending on power availability.

✔ Environment – Ensure durability for outdoor or harsh conditions.

✔ Control System – Consider manual, remote, or automated control.

🔹 Example: If you need a quiet and smooth actuator for an electric recliner, an electric linear actuator with a low-noise motor is ideal.

Conclusion

A linear actuator is an essential component in modern automation, providing precise and efficient linear motion. Whether used in industrial machines, medical devices, smart homes, or robotics, these actuators offer high performance, reliability, and control.

If you’re looking for high-quality linear actuators, visit Changxing Motion Tech to explore their advanced actuator solutions.

Frequently Asked Questions (FAQs)

1. What is the lifespan of a linear actuator?

Most electric actuators last several years with proper maintenance, typically 10,000 to 100,000 cycles.

2. Can I control a linear actuator with Arduino?

Yes! You can use an Arduino board with an H-bridge motor driver to control an electric linear actuator.

3. What is the maximum force a linear actuator can handle?

It depends on the type. Electric actuators can handle 100N to 10,000N, while hydraulic actuators can go beyond 100,000N.

4. Are linear actuators waterproof?

Some models have IP-rated protection (e.g., IP65, IP67) for outdoor and wet environments.

5. Can I use a linear actuator in extreme temperatures?

Yes! Some actuators are designed for hot, cold, or harsh industrial environments.

Why Choose Changxing Motion Tech for Linear Actuators?

- ✅ High-Quality & Durable Products

- ✅ Customizable Actuator Solutions

- ✅ Reliable Performance & Precision

- ✅ Industry Expertise & Support

👉 Need help choosing the right actuator? Contact Changxing Motion Tech today!