SLewing Bearing

Slewing bearings, also known as slewing ring bearings or turntable bearings, are critical components in various machinery. They consist of an outer ring, an inner ring, rolling elements, and seals. Our slewing bearings are made from high alloy-structural steels, such as 42CrMo and 50Mn, ensuring exceptional strength and durability. These bearings operate efficiently in temperatures ranging from -30℃ to +70℃. Additionally, we offer customized designs to meet specific customer requirements.

For more information on our high-quality slewing bearings, contact us.

Description

|

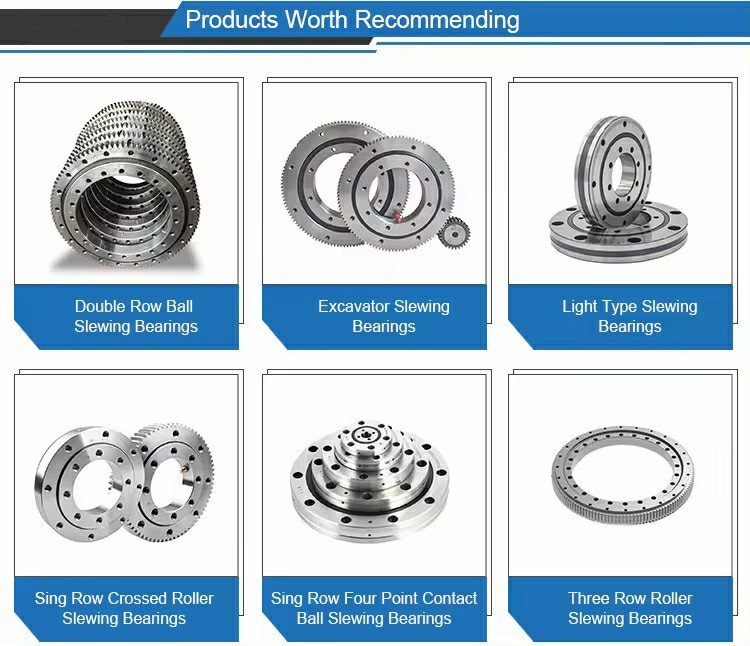

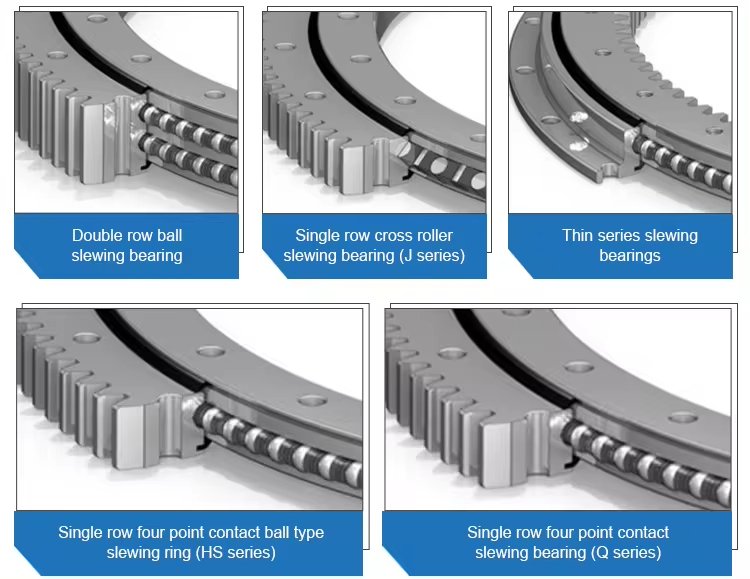

Product series

|

1. Single Row Four Point Contact Ball Slewing Bearings.

2. Single Row Crossed Roller Slewing Bearings 3. Double Row Ball Slewing Bearings 4. Three Row Roller Slewing Bearings 5. Thin Section Slewing bearings (Light type). 6. Thin Section Slewing Bearings (Flange type) |

|

Outside Diameter

|

300 – 5000 mm

|

|

Gear Options

|

External gear

Internal gear Without gear |

|

Brand Name

|

CX

|

|

Raw material

|

50Mn, 42CrMo

|

|

Certificate

|

ISO9001:2008, SGS

|

|

Payment Terms

|

L/C,T/T,Western Union

|

|

OEM/ODM

|

Available

|

|

Packaging Details

|

1:Filling with rust-proof oil

2:Packing with protective layers 3:Fixed in wooden box |

Introduction

Slewing bearings are critical mechanical transmission components extensively used in heavy machinery and industrial equipment. These bearings play a vital role in supporting and rotating mechanical structures, effectively bearing both weight and rotational forces.

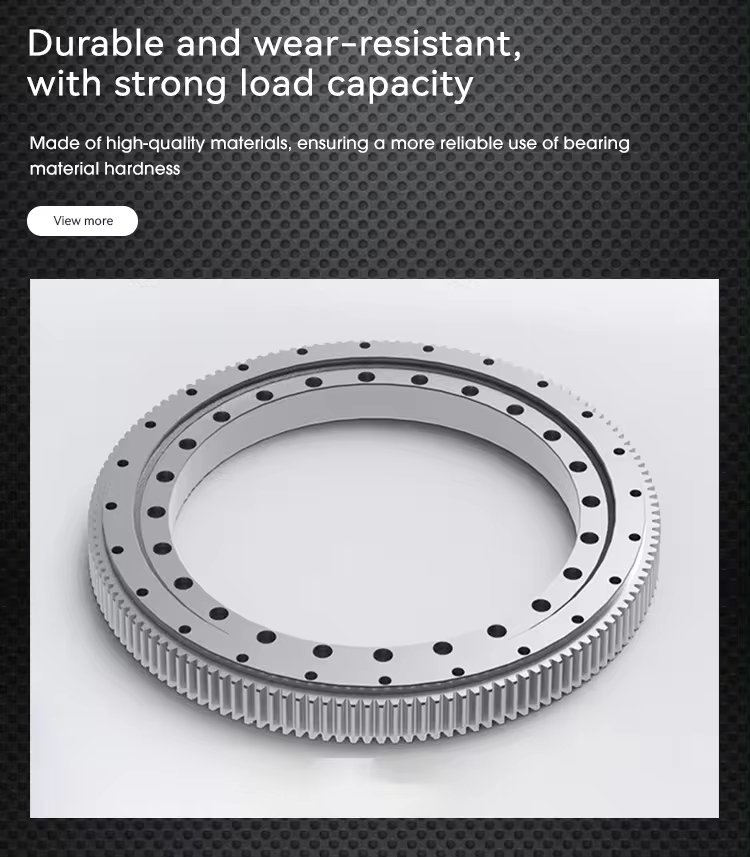

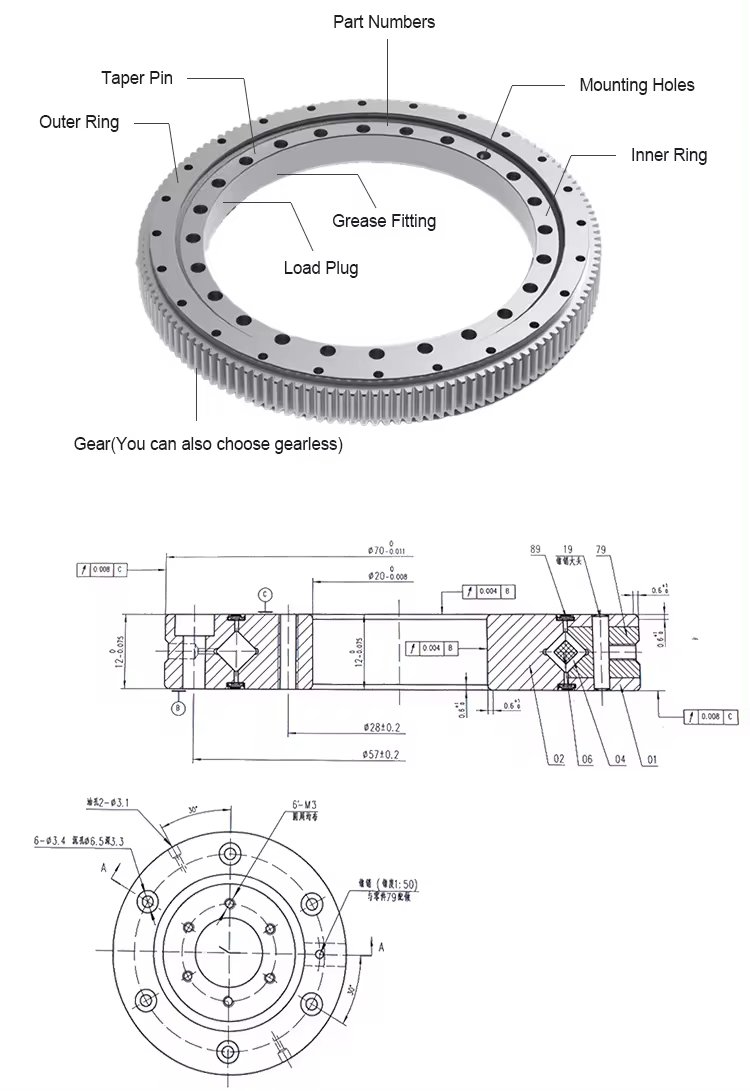

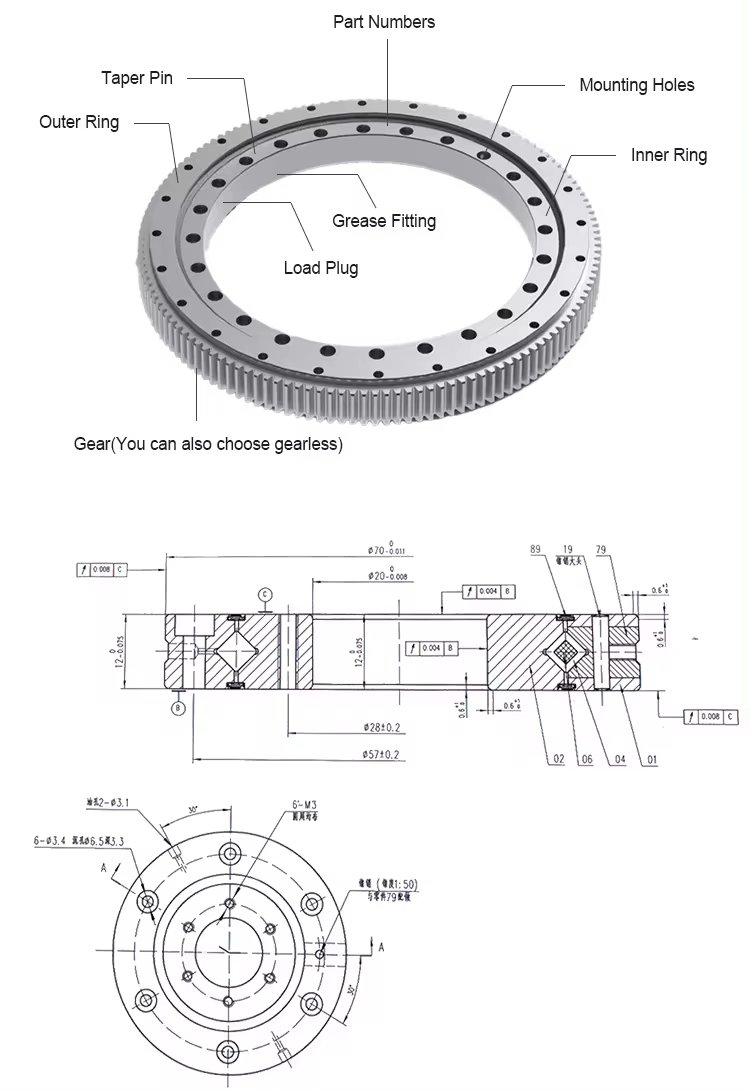

Composition and Design

Typically, a slewing bearing consists of an inner ring, an outer ring, and rolling elements. Precision machining and heat treatment are employed to ensure the bearings exhibit high strength and exceptional wear resistance. These features are crucial for the demanding environments in which slewing bearings operate.

Key Features

- High Load Capacity: Designed to handle both axial and radial loads, as well as tilting moments.

- Durability: Enhanced by precision machining and heat treatment processes.

- Versatility: Suitable for a wide range of applications, including cranes, excavators, wind turbines, and more.

- Optimized Performance: Ensures smooth and reliable rotation even under heavy loads.

Applications

Slewing bearings are indispensable in various sectors:

- Construction Machinery: Cranes, excavators, and concrete pumps.

- Industrial Machinery: Robotics, packaging machines, and assembly lines.

- Renewable Energy: Wind turbines and solar trackers.

- Marine Equipment: Offshore cranes, deck machinery, and ship loaders.

Why Choose Our Slewing Bearings?

- Precision Engineering: State-of-the-art manufacturing techniques guarantee superior quality.

- Extended Lifespan: Designed to withstand harsh conditions and heavy use.

- Comprehensive Support: Dedicated customer service and technical support to assist with installation and maintenance.

Reviews

There are no reviews yet.