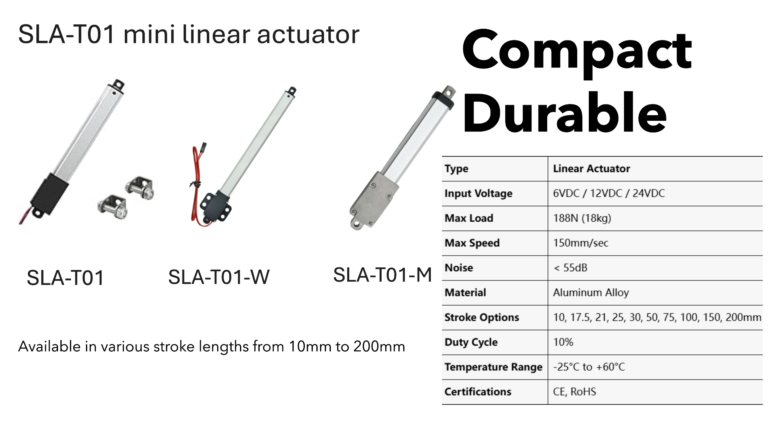

DC 6V 12V 24V optional 10mm stroke 188N 5mm/s mini linear actuator

(DC 6V / 12V / 24V):**

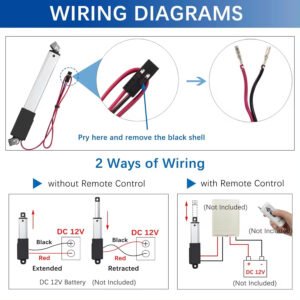

* This actuator is versatile and can be powered by various DC sources.

* 6V: Common for small battery-operated hobby projects or toys.

* 12V: The industry standard for automotive, marine, and general industrial automation.

* 24V: Often used in heavier industrial control systems or where voltage drop over long cable runs is a concern.

- Stroke Length (10mm):

- This is a very short travel distance (1 cm). It indicates the device is designed for micro-adjustments, locking mechanisms, or triggering switches rather than moving large objects over distances.

- Force (188N):

- 188 Newtons is approximately 19.17 kg or 42.2 lbs.

- For a “mini” actuator, this is a relatively high force rating. It suggests high torque gearing inside the motor. It can push or pull a significant weight for its size.

- Speed (5mm/s):

- This is a slow speed. It will take 2 seconds to fully extend or retract its 10mm stroke.

- Trade-off: In linear actuators, speed and force are inversely related. The high force (188N) is achieved by gearing the motor down, which results in this slower speed (5mm/s).

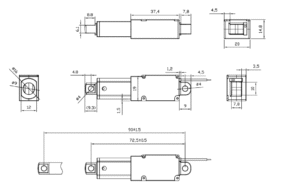

10mm stroke regular type linear actuator

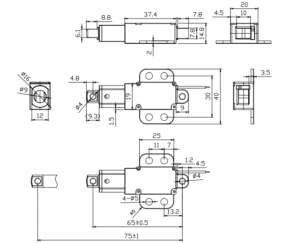

10mm stroke wing type linear actuator

Likely Applications

Given the combination of high force, short stroke, and compact size, this actuator is likely suitable for:

- Locking Mechanisms: Electronic door locks, cabinet latches, or safe boxes where a strong bolt needs to move a short distance to secure a door.

- Robotics: Gripper actuation (opening/closing a claw) or adjusting flaps/fins on drones or RC vehicles.

- Medical Devices: Precision dosing pumps or adjusting parts of a prosthetic limb.

- Automotive: Opening fuel tank flaps, trunk latches, or adjusting mirror angles.

- Smart Home: Automated window latches or vent openers.

Technical Considerations for Integration

If you are planning to use this component, consider the following:

- Limit Switches: Does the unit have built-in limit switches? If not, you must design your circuit to cut power when the actuator reaches the end of its 10mm stroke to prevent motor burnout.

- Duty Cycle: Mini actuators usually have a low duty cycle (e.g., 10-20%). They are not designed to run continuously; they need a “rest” period after moving to cool down.

- Mounting: Check the datasheet for mounting holes (clevis or flat mount). With 188N of force, the mounting brackets need to be sturdy.

- Current Draw: Ensure your power supply (battery or AC/DC adapter) can handle the peak current (stall current), which will be highest when the actuator is starting or pushing its maximum load.

- Website:www.changxing-motiontech.com

- E-mail:changxingsale@gmail.com

- whatsapp: +8618015001886